Wide Web CI Flexo Printing

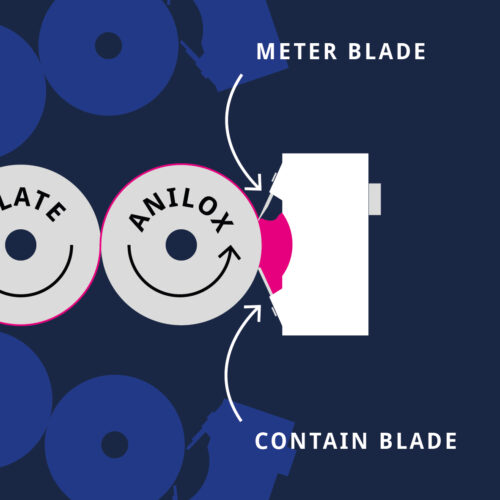

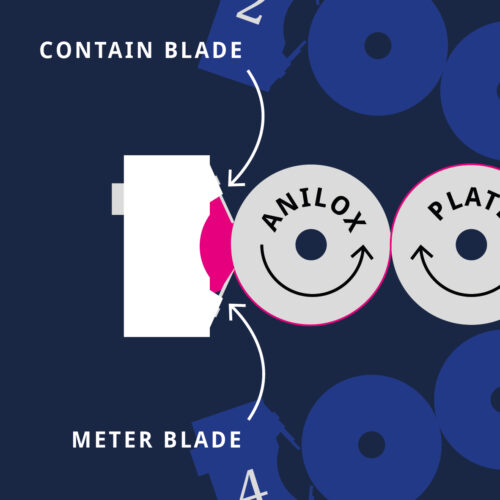

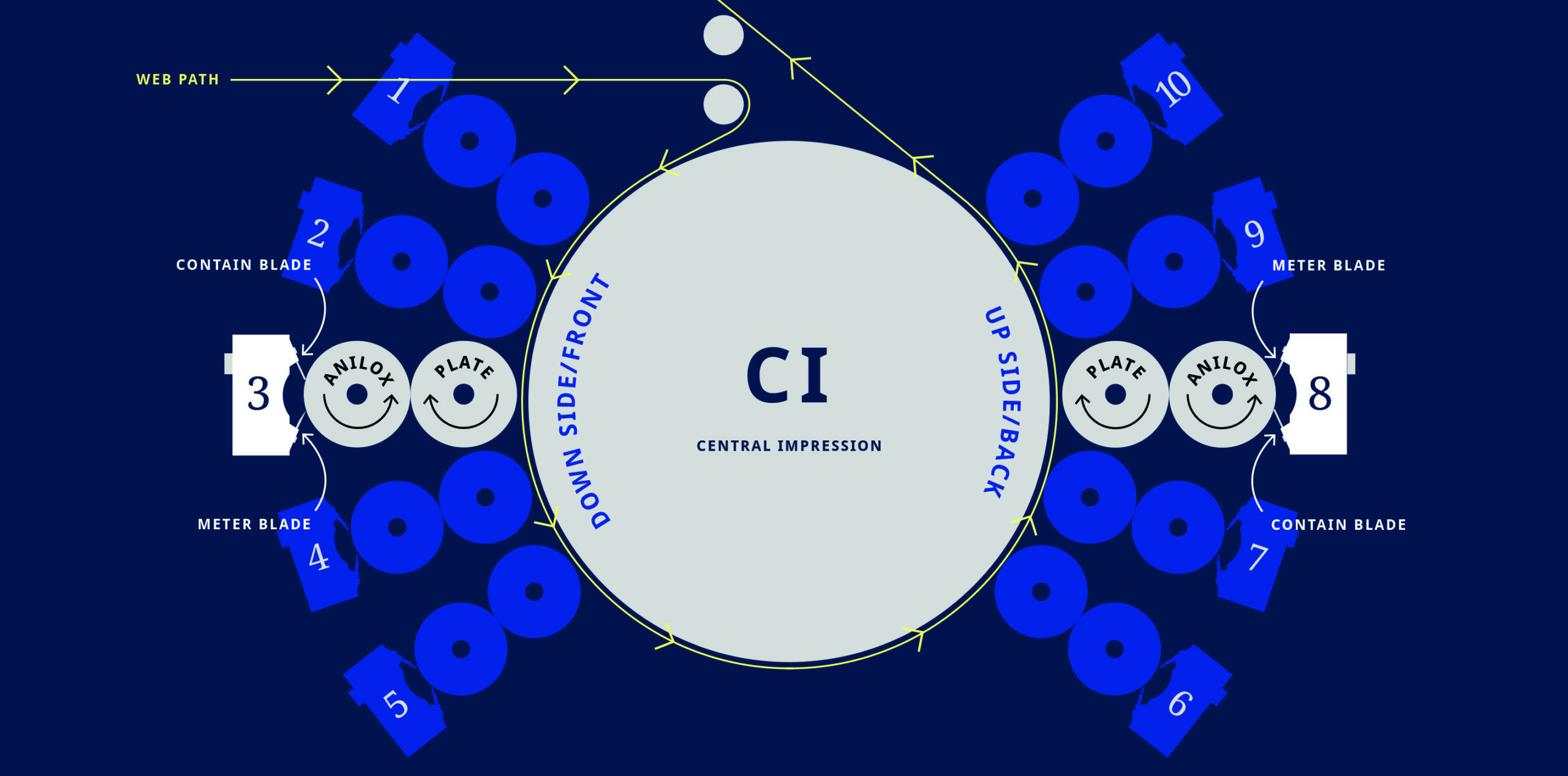

Precise ink metering is crucial to achieve high-quality flexo printing. Selecting the correct metering and containment blades as well as their set up and position in press is important. Doing it right can prevent dot gain, dirty print, end seal leaking, back doctoring and anilox damage or wear.

This article explains the importance of ink metering for high-quality flexo printing and provides guidance on how to set up the correct metering and containment blades. By following these instructions, you can prevent common printing issues and achieve precise ink metering for optimal printing results.

Metering and Containment Blades are Different

It is important to understand the differences between metering and containment blades, and to know they have a different purpose and require the use of different materials.

See our product range of doctor blades here.