H7

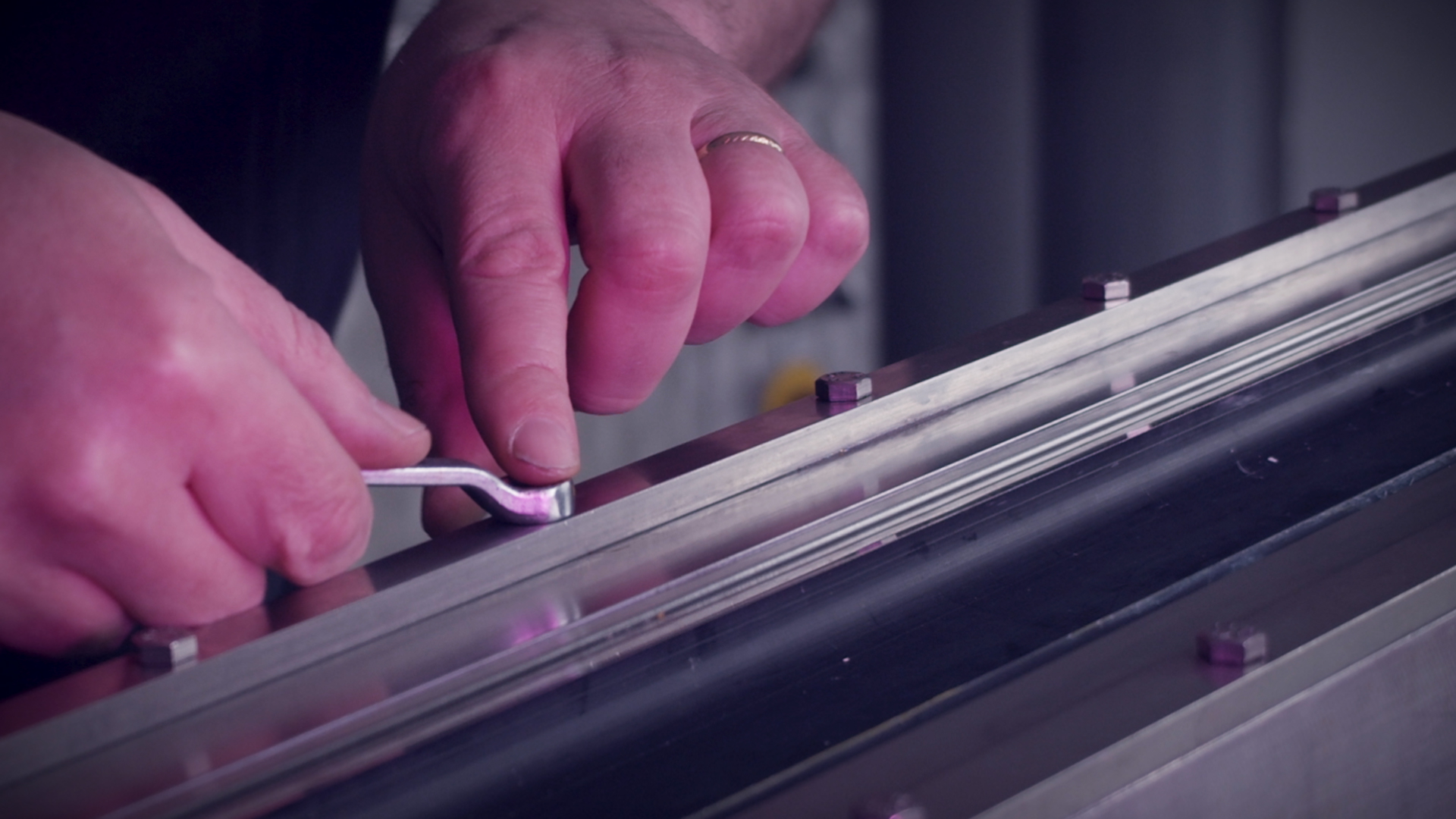

Swedcut® H7 is our solution for outstanding combination of printing results and the highest level of wear resistance. The special coating provides decreased friction which greatly increases performance.

The big benefits with the Swedcut® H7 is that it prevents particulate sticking and tolerates very high speed. Swedcut® H7 durable characteristics make the blade a perfect blade for long running times.

The Swedcut® H7 is a perfect choice for both flexographic and rotogravure applications when using abrasive inks.