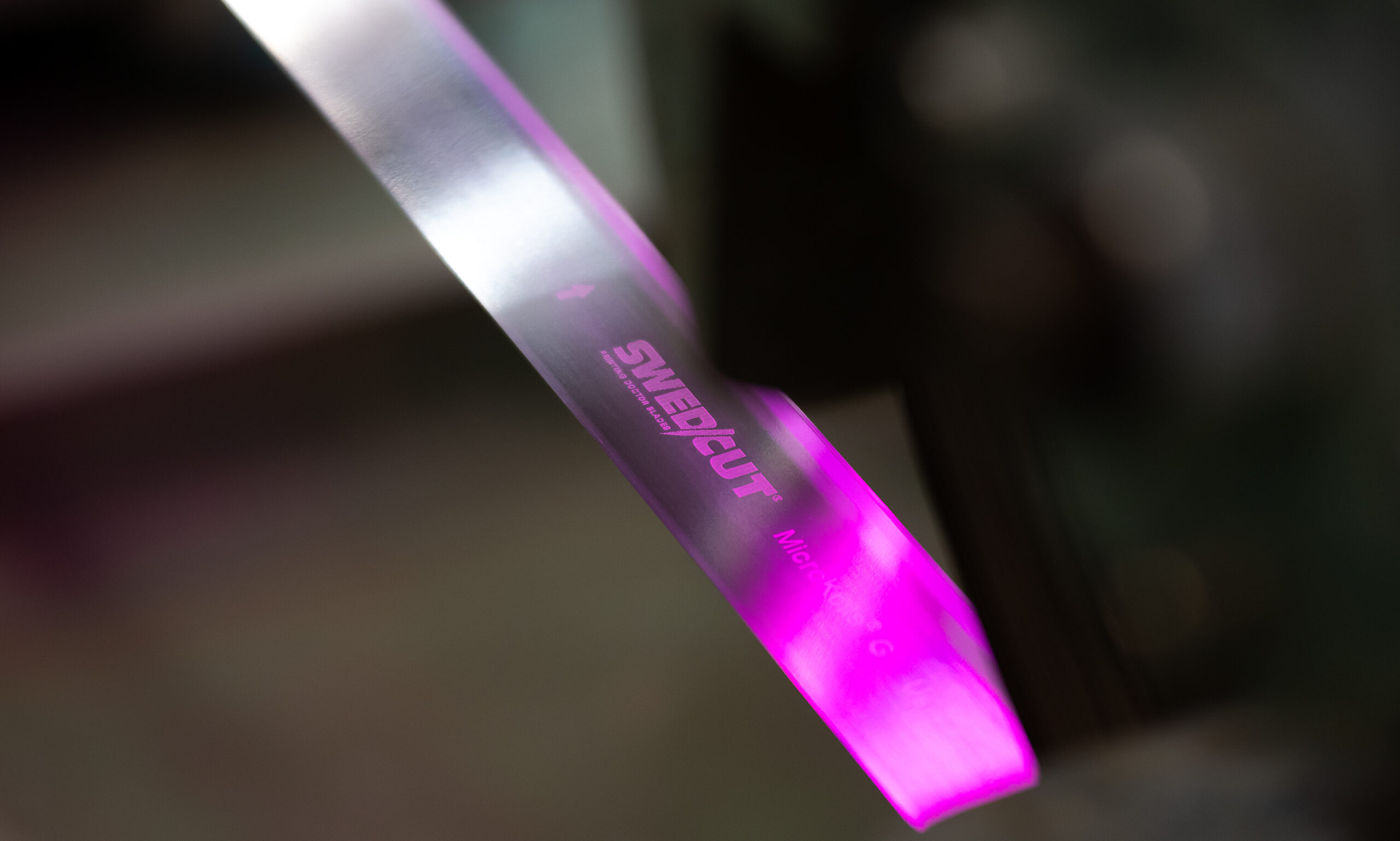

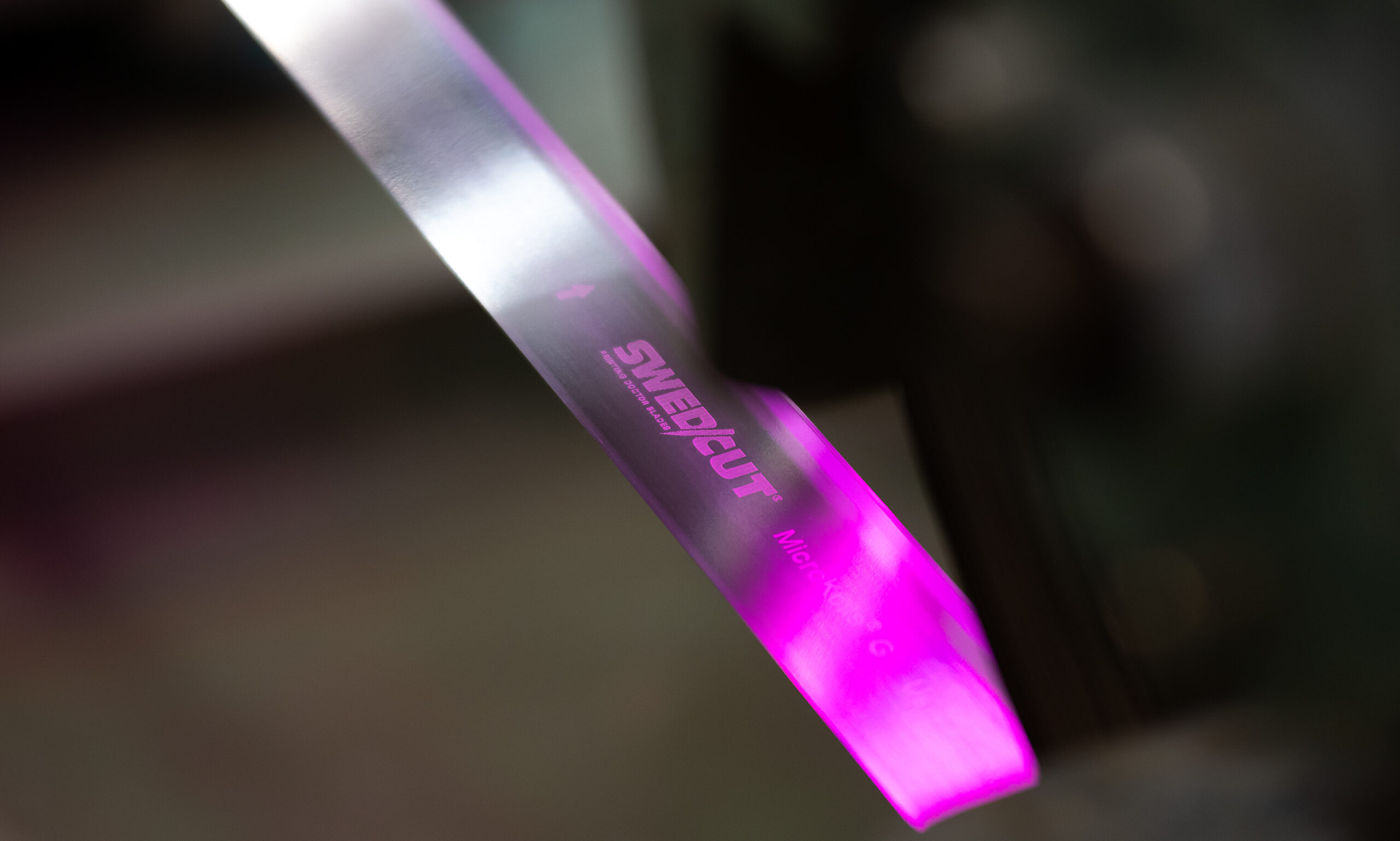

Why should you choose coated printing doctor blades? Because they offer several benefits, which makes them an excellent choice for printing operations. Overall, the coating improves printing quality and reduces downtime.

We all know that the doctor blade plays a big part when it comes to your printing quality. Coated printing doctor blades decrease friction between the doctor blade and the cylinder/anilox. The coating also can help ensure a more uniform and consistent printing surface. This means a reduction when it comes to wear, ink spitting, and printing defects. In other words, coated printing doctor blades improve your printing quality because the coating provides a more consistent ink transfer.

Beyond decreased friction, coated doctor blades also can reduce wear on the cylinder/anilox thanks to its lubricating effect. By choosing a coated blade you extend its life and prevent unnecessary replacement costs.

Did you know that coated blades are corrosion-resistant? Using printing doctor blades that are corrosion-resistant means your blade gets a longer life. For you, that means reduced downtime and reduced waste.

Coated blades have smoother wearing characteristics thanks to reduced friction and the lubricating effect. For you, this means that you will get results with more consistent performance, improved printing quality, and consistency of your printed products.

See our product range of doctor blades here.

Uncoated doctor blades also come with many benefits and remember that the most important thing is to choose the right blade for the right application.

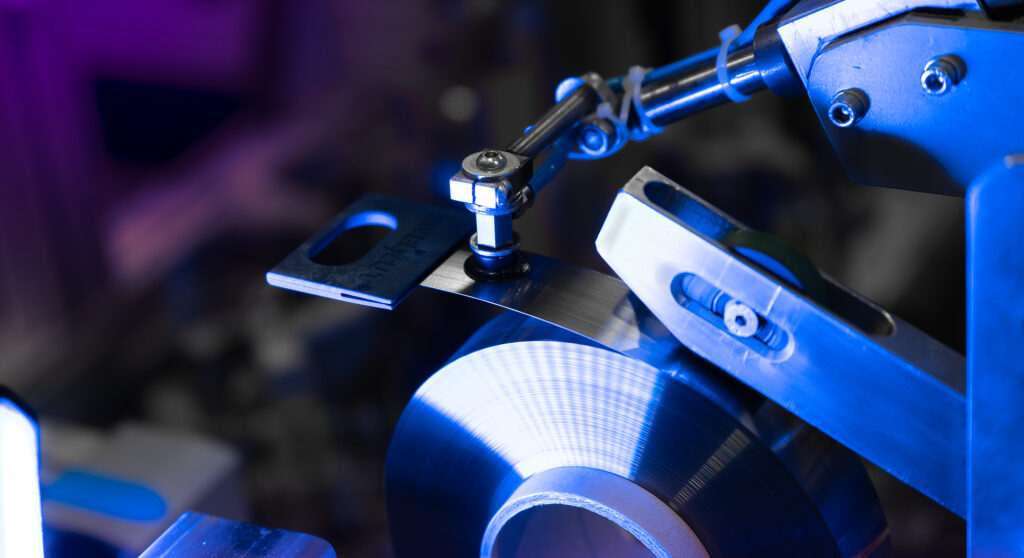

Also, remember to install the blade correctly for the best results. If you feel unsure, check out this link for tips and tricks, or feel free to contact us anytime.